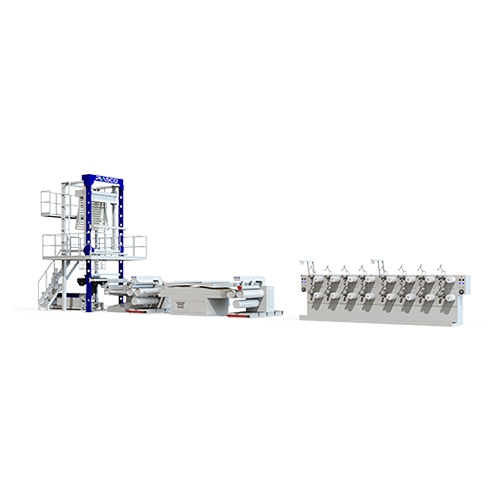

Линия для производства обвязочной ленты и шпагата (Серия JC-BFY)

КАТЕГОРИИ : Выдувание пленки

Работа линии серии JC-BFY основана на применении метода экструзии пленки с раздувом и специально разработана для изготовления вязальной ленты, многониточного шпагата, скрученного шпагата для легкой упаковки, а также другой упаковки общего и промышленного назначения.

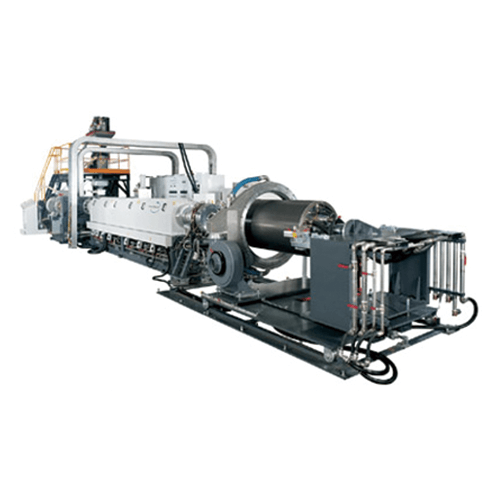

Линия фибриллированной ленты(Серия JC-FYB)

КАТЕГОРИИ : Линии экструзии для волокон и пряжи

Линия экструзии фибриллированной ленты серии JC-FYB производит фибриллированную ленту для обычных и тяжелых условий эксплуатации для широкого ассортимента продукции, такой как шпагат для обвязки тюков, изолированный кабельный наполнитель, основа ковровых покрытий и искусственная трава.

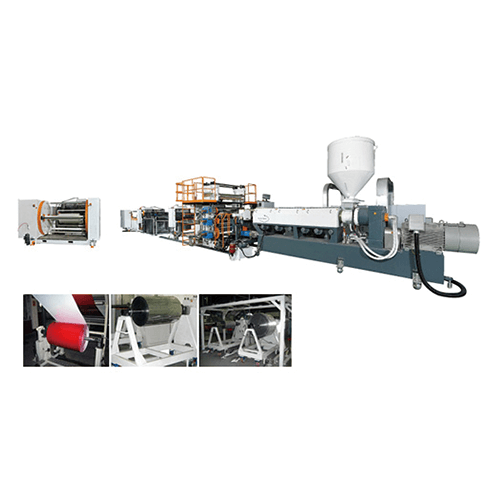

Foam Sheet Extrusion Line

КАТЕГОРИИ : Линии экструзии пленки и листа

Foam Sheet Extrusion Line Features : With proper mixing of melted resin & blowing agent, provides most homogeneous mixing. Accurate blowing agent injecting quantity and temperature control to stabilize the foaming process. High level safety control, system will be shut down automatically when extruder motor failure or high pressure.

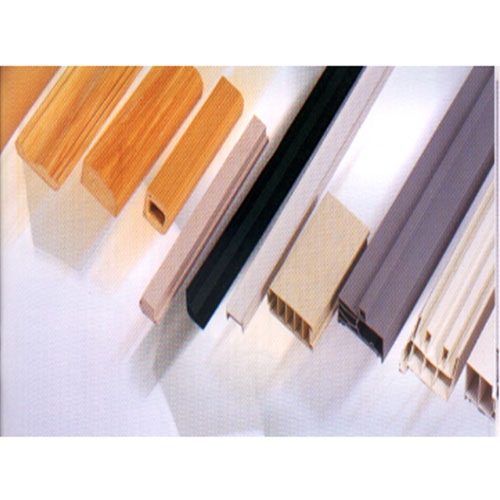

EXTRUDER FOR PVC/TPO SOFT FILM

Fruitive International Co. helps consult and design different types of PVC / TPO soft products extrusion line for customers and suitable for a variety of PVC / TPO soft products production. It is applied to products such as PVC tablecloth, shower curtain, tiles backing, transparent film car decorative, flloring, TPO tablecloth, printed film and so on. The extruder and calender unit that consists of rollers is also the core equipment of a production line. Hence, this is important when choosing the right products. We always make every effort to assist our clients to select the requested products in regarding to some technical aspects such as length and diameter ratio of the extruder, the width and the material of the calendar roller with the maximum capacity in order to meet the aimed production capacity and product demands. We achieve making the best thickness contribution by adopting the technology of moving rollers, roll bending, and other means. It is also an option to equip the most up-to-date full automatic control as well as the thickness monitor on our calenders.

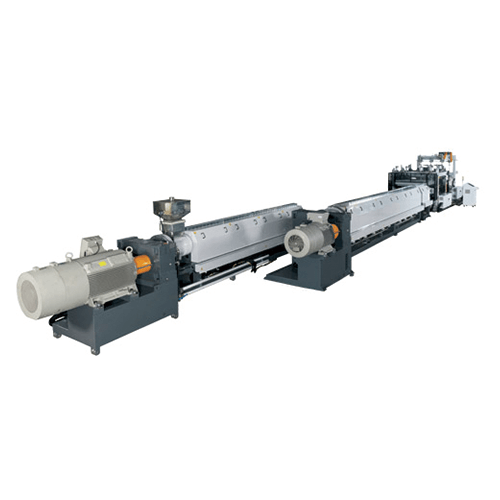

Rigid Sheet Extrusion Line

КАТЕГОРИИ : Линии экструзии пленки и листа

1. Extruder is driven by AC Inverter duty motor, with excellent efficiency and lowest power consumption. 2. Extruder hopper with low-level sensor work with auto-feeder will keep material in stable supply. 3. Hydraulic driven screen changer avoid any particle goes to melting pump & flat-die. 4. Melting pump with accurate rotation control, keeps the material flow stable. 5. Extruder & melting pump speed is working on pressure synchronized controlling system.